Definitive Measures Against Stress Corrosion Cracking (SCC): Shot Peening

Many kinds of metals are used for tanks, support frames, and structural components in oil refineries and chemical plants. However, under certain conditions, metal corrosion can progress, potentially leading to sudden fracture. One such phenomenon is stress corrosion cracking (SCC).

This article introduces the causes, countermeasures, and specific measures against SCC.

Basic Knowledge of Stress Corrosion Cracking (SCC)

What is Stress Corrosion Cracking (SCC)?

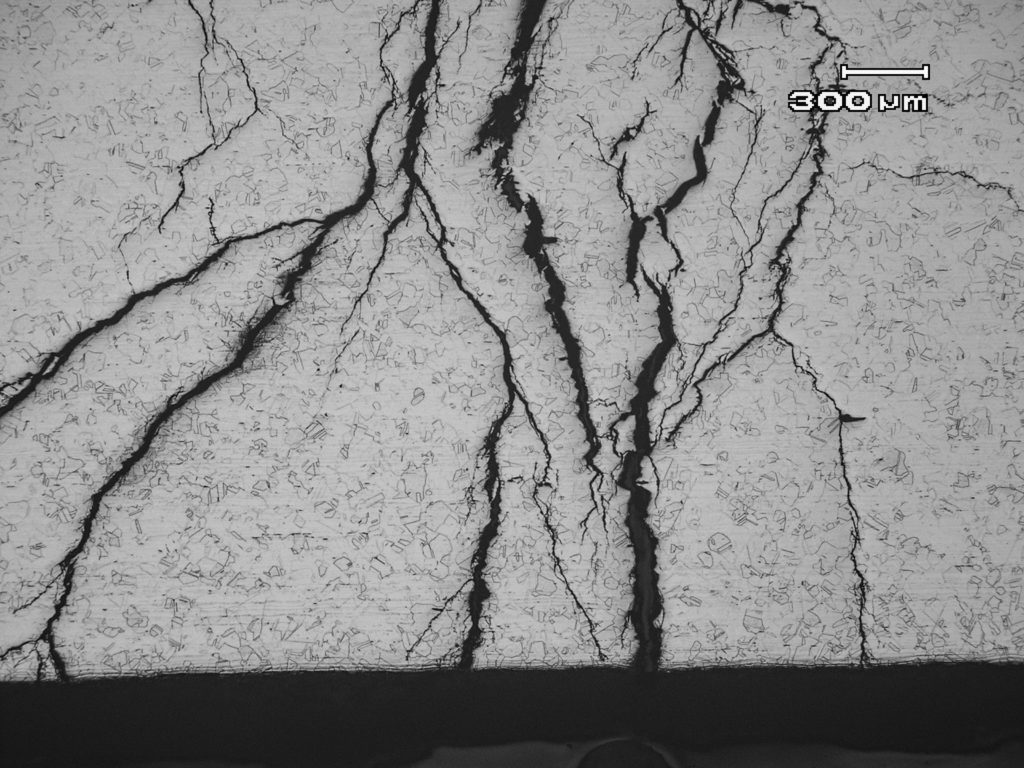

SCC refers to localized damage that occurs when tensile stress is induced to a material in a specific environment. As the name suggests, SCC occurs when three conditions—stress (mechanical conditions), corrosion (environmental conditions), and material properties—are combined. If left untreated, SCC progresses (worsens), starting as a crack less than 1mm but eventually reaching the other side and causing fracture.

Materials Prone to Stress Corrosion Cracking (SCC)

Several materials are prone to SCC, including austenitic stainless steels such as SUS304 (ISO 3506-1) and SUS316 (ISO 3506-1). Austenite is one of the metallic structures of stainless steel, containing chromium and nickel, making it highly resistant to corrosion and heat, commonly used in plant equipment. Other materials prone to SCC include carbon steel and brass. SCC does not occur in pure metals but in alloys.

Causes of Stress Corrosion Cracking (SCC)

1. Material Factors

One cause of SCC is material-specific factors. As mentioned earlier, austenitic stainless steels, carbon steel, and brass are well-known metals susceptible to SCC.

2. Environmental Factors

While certain materials are prone to SCC, the surrounding environment (solutions, atmosphere) is also a factor. The solutions and atmospheres that cause SCC vary by metal (Table 1).

Table 1: Metals and environmental factors that can cause SCC

| Metal | Cause | Surrounding Environment |

|---|---|---|

| Austenitic Stainless Steel | CL- | High-temperature seawater |

| OH- | High-temperature, high-concentration NaOH solution | |

Polythionic Acid | Exposed to sulfur and humid environment | |

| High-Temperature Water | Boiling water reactor piping | |

| Carbon Steel | NO3- | High-temperature NaNO3 solution |

| OH- | High-temperature, high-concentration NaOH solution | |

| Brass | NH3 | Atmosphere containing NH3 |

| Amine | Aqueous solution of amine |

Austenitic stainless steel is particularly susceptible to SCC from chloride ions, so much so that it is said to always crack under tensile stress. A case in a nuclear power plant involved SCC caused by a vinyl chloride tape applied to austenitic stainless steel piping.

High-strength steel is vulnerable to H2S solutions, and high-strength aluminum and titanium alloys are vulnerable to seawater.

3. Mechanical Factors

The third factor in SCC is tensile stress.

For example, austenitic stainless steel normally requires heating above 850°C to relieve stress. However, in practice, this temperature is not reached, and sufficient stress relief is not achieved, leaving tensile stress in welded areas.

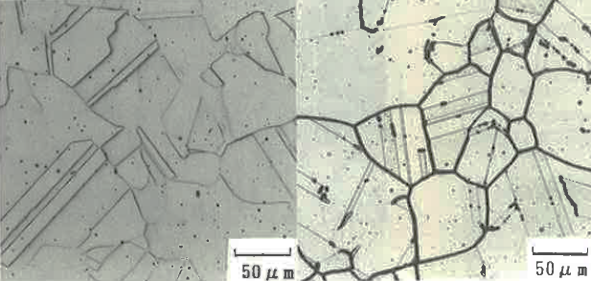

Residual stress after welding occurs due to "Sensitization". Exposure to high temperatures causes chromium to bond with carbon, forming carbide compounds. As a result, the chromium-depleted areas increase, reducing corrosion resistance near grain boundaries, making them prone to corrosion. SUS304 (ISO 3506-1) is said to sensitize when exposed to 600°C–800°C for 10 minutes to 1 hour.

Eliminating any of these three factors can prevent SCC.

Countermeasure Technologies for Stress Corrosion Cracking (SCC)

1. Countermeasures for Material Factors

Upgrading Materials

Avoiding the use of materials prone to SCC would be ideal. However, changing materials is not simple. For example, SUS304 is often useful due to its cost-performance, even though it has sensitization risks.

Common considerations include using SUS316 (ISO 3506-1 (A4)), which has better corrosion resistance than SUS304 (ISO 3506-1 (A2)), or SUS304L (ISO 3506-1 (A2L)) and SUS316L (ISO 3506-1 (A4L)) with lower carbon content. SUS304 (ISO 3506-1 (A2L)) typically contains 0.03%–0.08% carbon, while SUS304L (ISO 3506-1 (A2L)) contains less than 0.03%. Lower carbon content reduces carbide formation, making it less prone to sensitization.

Even with high-grade materials, SCC cases frequently occur in heat-affected zones from welding or grinding. Cases also exist where duplex stainless steel or Hastelloy was used, yet SCC still occurred.

Therefore, upgrading materials alone is realistically difficult for preventing SCC.

2. Countermeasures for Environmental Factors

Adding Corrosion Inhibitors

Using corrosion inhibitors can slow SCC progression in carbon steel and other materials. Types of corrosion inhibitors include passivation film types (chromates, nitrites) that lower metal ionization tendency and form a passive film, and adsorption types (amines) that inhibit corrosion by attaching organic compounds to the surface.

Corrosion inhibitors can be used on finished equipment, but identifying the SCC-causing components, often by-products from the manufacturing process, is challenging. Managing the amount of inhibitor added is difficult, and contamination can negatively impact end-users, making this countermeasure difficult to apply.

Thermal Spraying (Anodic Protection)

Thermal spraying involves heating and melting the spraying material, which is then atomized with compressed air and sprayed onto the substrate. The sprayed material mechanically bonds with the pre-treated substrate, forming a coating.

The sacrificial coating corrodes first, protecting the substrate. However, the coating gradually thins, requiring periodic re-treatment. Additionally, the coating must be removed during regular crack inspections.

3. Countermeasures for Mechanical Factors

PWHT (Post Weld Heat Treatment)

PWHT involves passing an electric current through a heating element attached after welding to reduce residual stress and prevent welding embrittlement. There are furnace heat treatment and localized heat treatment methods, applied to weld areas (such as elbows) in piping.

SCC resistance improves as grain size is refined, but applying PWHT to large structures is difficult. Applying it to heat-affected zones from welding or grinding during equipment installation is also challenging. Heat management is complex, and errors can lead to equipment buckling.

Shot Peening

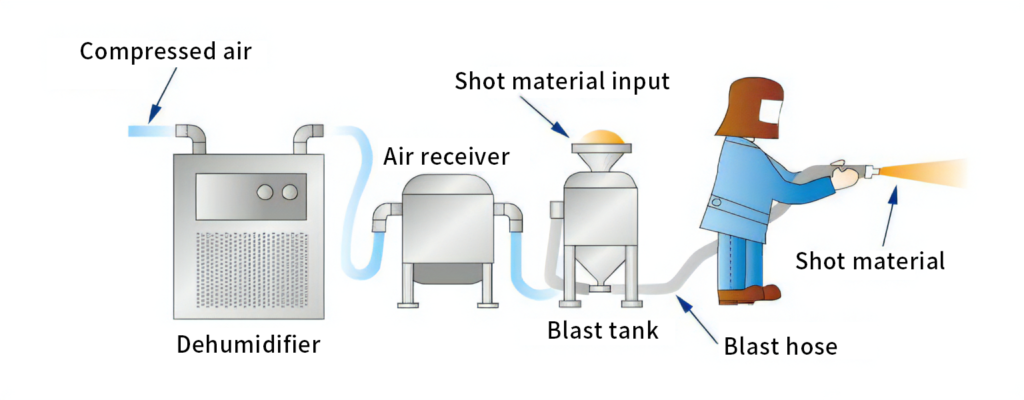

Shot peening involves striking the substrate with spherical particles (shot) to harden the surface. Tensile residual stress from welding causes SCC, but shot peening can introduce compressive residual stress, providing an effective SCC countermeasure.

Shot peening is effective for heat-affected zones from installation welding or grinding, which are particularly prone to SCC. It is also suitable for large areas or difficult-to-access areas, such as confined spaces and pipe interiors, where PWHT or pneumatic hammers are ineffective. However, managing the parameters requires expertise, making the selection and track record of the contractor crucial.

Kanmeta’s Premium Shot Peening Technology

Reasons to Recommend Shot Peening

Shot peening brings compressive residual stress to a certain depth, not just the surface, effectively removing SCC causes in the treated areas. It allows SCC prevention only in necessary areas. The depth and magnitude of compressive residual stress depend on the selected shot material and related parameter settings, and proper process management is crucial.

We are the pioneer in applying shot peening to SCC, setting parameters and quality management methods from a scientific perspective with Prof. Mikio Takemoto of Aoyama Gakuin University, an authority on SCC and our advisor.

About Our Shot Peening Service

Kanmeta Engineering has developed shot peening used as an SCC countermeasure on-site, with a track record of 5,000 m² of cumulative work mainly in major oil refineries and petrochemical plants. We respond flexibly to sudden problems and can handle large-scale areas. We also have a dedicated processing booth at our factory for handling target parts.

• Crack PT inspection after treatment is possible

• On-site stress measurement with X-ray equipment (optional)

• Selection of high-grade shot materials with high peening effect is possible

Contact Us

For executives facing SCC countermeasures who wish to implement treatment "immediately," please consult Kanmeta Engineering.